extreme is our business

STÖHR ARMATUREN ist seit 1960 auf die Entwicklung und Fertigung von Armaturen für Gase spezialisiert.

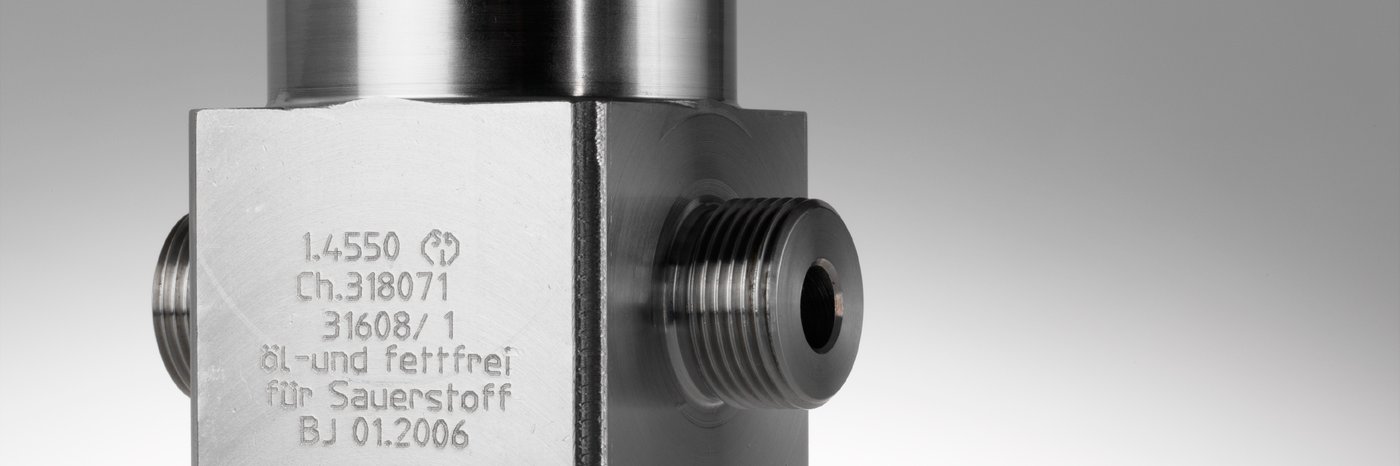

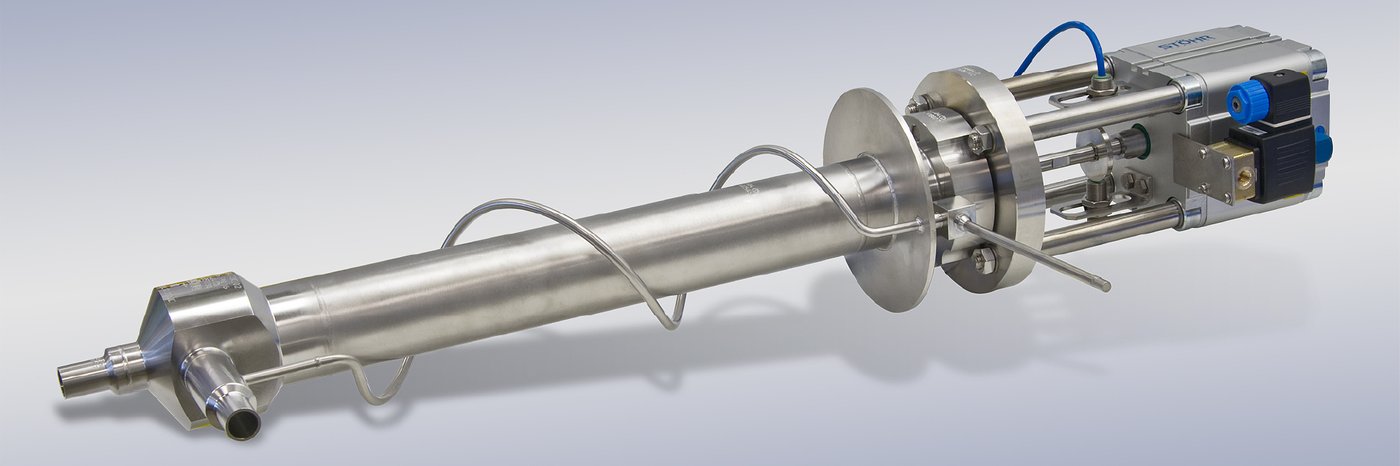

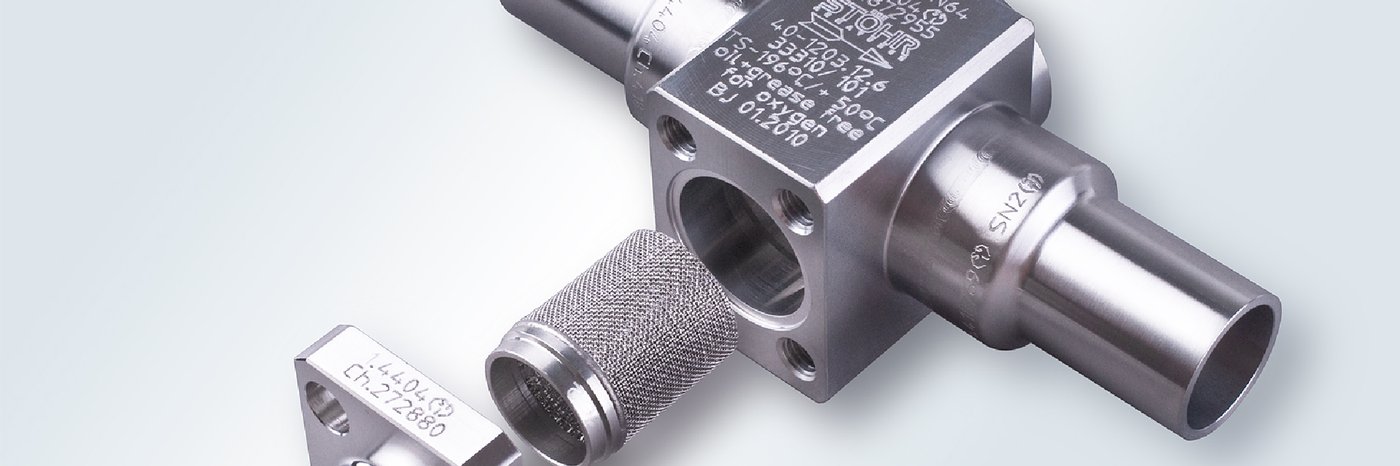

Tiefkalte Temperaturen bis zu 4 K und darunter zur Verarbeitung von Flüssig-Helium, hoher Druck bis zu 1.000 bar, hohe Dichtheit gegenüber der Atmosphäre, hohe Verträglichkeit gegenüber den unterschiedlichsten Medien, XXL-Ventile mit Nennweiten bis DN300 sowie kurze Öffnungs- und Verschlusszeiten sind beispielhaft für die extremen Anforderungen an die Produkte von STÖHR ARMATUREN.

Zu unseren langjährigen Kunden zählen weltweit namhafte Unternehmen aus der Gase-Industrie, Chemischen Industrie, Raumfahrt, Marinetechnik, Energietechnik sowie Forschungseinrichtungen.

Unsere Erfahrung setzen wir konsequent für Sie um – in hochwertige Standardventile mit zahlreichen Optionen wie auch kundenspezifische Spezialventile – bei konstant hoher Qualität.

Qualität ohne Kompromisse – meet the extremes!

Finden Sie die passenden Ventile von STÖHR ARMATUREN je nach Einsatzgebiet, Ventilfunktion, Medientemperatur oder Nennweite mit Hilfe unseres Produktfinders.

Produktfinder

Armaturen von STÖHR finden seit Jahrzehnten Anwendung in unterschiedlichen Branchen weltweit. Verschaffen Sie sich einen Überblick über deren Einsatzmöglichkeiten.

Zielmärkte

XXL – Ventile mit Faltenbalgabdichtung bis DN300, eine Klasse für sich. Die Anwendung bestimmt die Größe. STÖHR ARMATUREN – Ventilfunktionen auch in den größten Größen.

Von XXS bis XXL

Ventile von STÖHR, seit jeher für H2 geeignet, unterstützen die schnelle Energie-Transformation und Versorgung mit grünem Wasserstoff in den entscheidenden Anwendungsbereichen.

www.stoehr-hydrogen.de

Im öffentlichen Download-Bereich stehen Ihnen Produktkatalog, Broschüren, Veröffentlichungen und vieles mehr zur Verfügung:

Download

Was macht unsere Ventile so ausdauernd, und warum steckt der Chili im Eiswürfel? Es gibt Fragen zu unseren Produkten, die wir nicht unbeantwortet lassen wollen!

Fragen und Antworten

Nicht jeder kann alles wissen - dafür haben wir aber für alles einen Ansprechpartner. Ob für eine einfache Frage oder die Klärung schwieriger technischer Zusammenhänge: suchen Sie das Gespräch mit uns!

Kontakt

STÖHR ARMATUREN bietet Anstellungen mit fachlicher Herausforderung, einen sicheren Arbeitsplatz und kollegiale Zusammenarbeit im Team. Wir stehen auch jeder Initiativbewerbung offen gegenüber.

Stellenangebote

Hochwertige Armaturen für anspruchsvolle Märkte

Best for Helium - damit nichts verloren geht. Wir bieten Lösungen für Anwendungen von Flüssig-Helium. Ventile von STÖHR ARMATUREN optimieren Aufwand und Kosten für einen effizienten Transport des Mediums zu und innerhalb ihrer Anlage.

Best for Helium

Im 24/7/52-Dauerbetrieb sind Ventile von STÖHR ARMATUREN trotz erprobtem Design, der Verwendung der besten Materialien und sorgfältiger Verarbeitung nicht vor Verschleiss gefeit. Sollte es dazu kommen, bieten wir hierfür Unterstützung:

Ventilservice

Messen, Kongresse, Fachveranstaltungen: Wir suchen gerne die Möglichkeit, informative Gespräche mit Ihnen zu führen, unsere Produkte zu zeigen und uns mit Ihnen auszutauschen.

Messen, Kongresse

Sie wollen wissen, wer hinter den Produkten von STÖHR ARMATUREN steckt, und was wir seit 1938 unternehmen, um erfolgreich hochwertige Produkte für den weltweiten Markt zu entwickeln und zu fertigen?!